Introduction: Value stream mapping is a lean-management method for analysing the current state and designing a future state for the series of events that take a product or service from its beginning through to the customer. At Toyota, it is known as “material and information flow mapping”. It can be applied to nearly any value chain.

Department

Name of Faculty

Mechanical Engineering

Prof. Swapnil Nawale

Applications

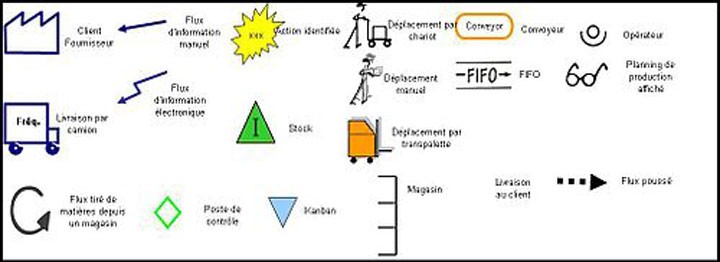

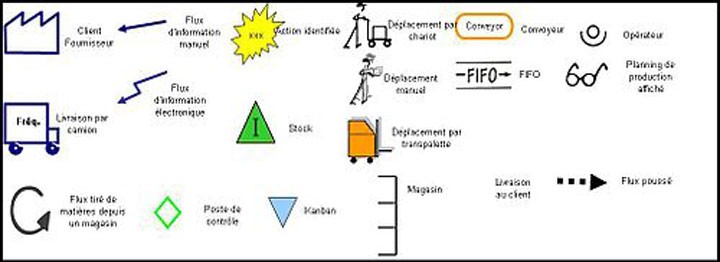

Value Stream Maps are usually drawn using a set of standard symbols, some of which can be seen here.

Value stream mapping has supporting methods that are often used in Lean environments to analyze and design flows at the system level (across multiple processes).

Although value stream mapping is often associated with manufacturing, it is also used in logistics, supply chain, service related industries, healthcare, software development, product development and administrative and office processes.

Value stream mapping is a recognised method used as part of Six Sigma methodologies.

This seminar was very helpful for students to understand practical applications of mechanism in vehicles. The response from the students for the particular topic was overwhelming. This topic fulfils the gap in the curriculum for theory of machines subject.